- Current Price

- :

- ¥

- 0

- Market Price

- :

¥0

- 實體商品

- In Stock

- Collection

- 商品詳情

- 產(chǎn)品參數(shù)

Usage Description:

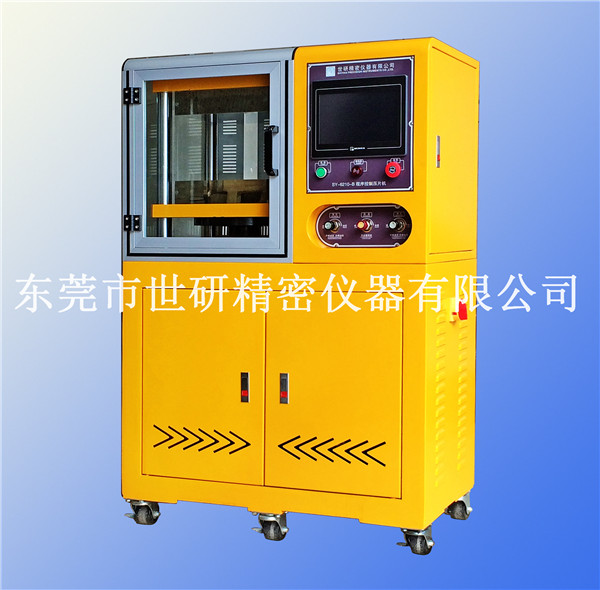

The raw materials are placed in the mold and sandwiched between the electric heating plates of the tablet press to apply pressure and temperature, forming the raw materials for testing and serving as the basis for mass production of ingredients in the factory. This machine is equipped with a PLC program controlled color touch screen, and the human-machine interface operating system can set pressure, temperature, time, and exhaust frequency. The vulcanization process is displayed and monitored in real-time, and all molding programs are automatically completed.

Typical applications:

■ Detection of gel (fish eye), black spot, stain, etc. of raw materials

Raw material tablet pressing, color matching, mixing, and sample preparation

Physical property testing

Material research and development